Mohamadou Mbengue, Rafael Monnerat, Jingjing XU, Ni Yan |

Packing Lists

Session 4: Sale Packing Lists

This visual guide is part of a collection of documents created by the One Student One ERP (OSOE) project in collaboration with Institut Mines Telecom, Telecom Bretagne, Dresden University of Technology and the South Westfalia University of Applied Sciences. It can be used to teach modern ERP theory and practice to undergraduate students or professionals.

Copyright: You are free to copy, distribute, display, and perform the work under the following conditions: you must attribute the work in the manner specified by the author or licensor; you may not use this work for any commercial purposes including training, consulting, advertising, self-advertising, publishing, etc.; you may not alter, transform, or build upon this work. For any reuse or distribution, you must make clear to others the license terms of this work. Any of these conditions can be waived if you get permission from the copyright holder through a commercial license or an educational license. For more information, contact info@nexedi.com

Agenda

- What is a Packing list?

- Why do we use "Divergence"?

- What is the delivery process?

- What is a "Container"?

Following the last session "Sale Orders", in this session, we will learn how to manage the Sale Packing List created from a Sale Order. We will also learn to generate a related Sale Invoice from a "Delivered" Sale Packing List.

Note: in this session "Sale Packing Lists", we will still use the company Hongzhao. So when you are practicing, please replace Hongzhao with the company you created when you configured your ERP5 instance.

Trade documents - Packing Lists

During the trade process, every company is producing documents. As you have learned from "Presentation of Sale Orders and Products", there are three main documents involved within this trade process: the Order, the Packing List and the Invoice, and each of them represents a step in the overall trading process.

This session is about the Packing List module, which comes just after the Sale or Purchase Order.

Packing Lists - why?

Why is a Packing List useful in an ERP system?

We could think that we have everything integrated in the Sale/Purchase Order, we already know which quantity of which product has been sold, so that we can know what the movement of goods related to this Order will be.

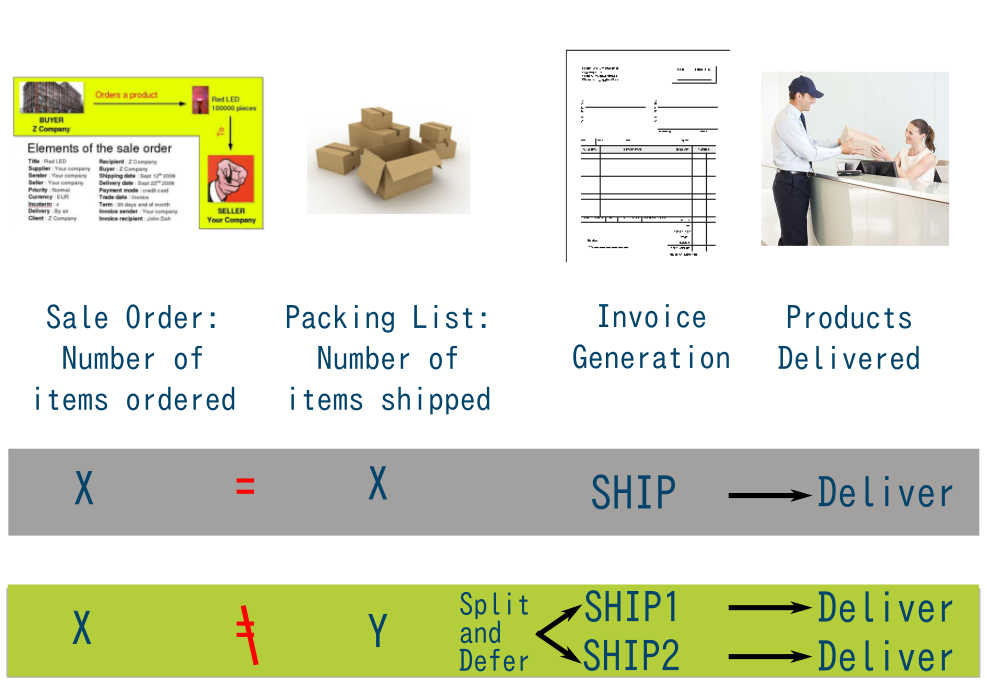

But in fact this is not true. It is not because an Order has been made for a specific quantity of a specific product so that it means we are going to deliver exactly what has been ordered.

For many different reasons, we might decide to deliver another product, or to deliver more or less products than what has been ordered.

For example, the customer ordered three different kinds of products, if we are missing one in stock, we may decide to send the two that we have, and to send the last one when it will be available. This is why we need to use Packing List to manage the divergence between the ordered products/services and the delivered products/services , and so on we can manage the related invoices and payments for each shipments in a more efficient way.

We will now see the different uses which can be made of the Packing List.

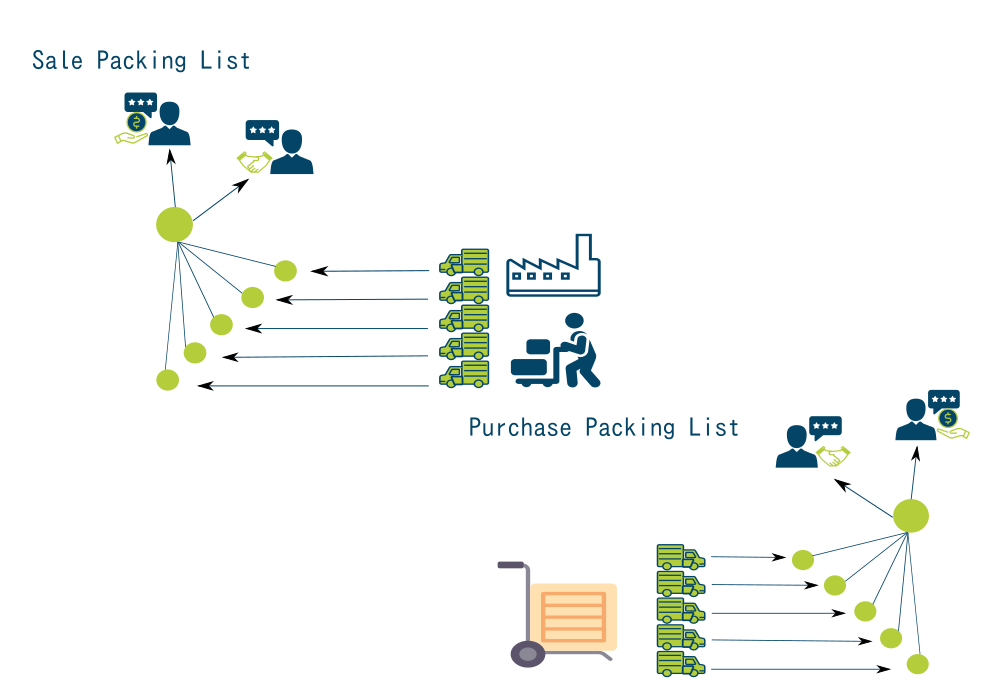

Packing Lists - Managing the stock

The most important aspect of the Packing List for the system is that it lets us manage our stock of products or services . As we have seen previously, we can't base the stock management on Sale or Purchase Order. In the company's business life, there will be many reasons why we won't deliver or receive goods or services which have been ordered. We can't base the stock management on the Invoice module either. Once again, there will be many cases when we will deliver or receive goods or services which won't be invoiced.

The only way to keep track of the stock is then to use the Packing Lists.

Packing Lists are used when we prepare the goods to be sent to the customer, or when we receive the goods from a supplier. We have the Order document, so we know what should be sent/received. As we have seen previously in the tutorial "How to create Sale Orders", in ERP5, the confirmed Order will automatically generate a Packing List for the following trade process.

Then we will prepare the goods and validate the Packing List. If we follow what was planned in the automatically generated Packing List, everything is fine. But if we don't send the correct quantity, we can still change it on the Packing List.

Similarly when we receive goods after sending a Purchase Order, an "expected" Packing List is generated. When we receive the goods, we can compare it with the Packing List of the supplier , to see if the goods we received are the same as on the paper. Then once we verify the goods, we can correct the received Packing List if required.

In one word, by using Packing Lists, we will have a better stock management.

Packing lists - Managing the containers

Packing Lists also manage the containers. Containers are everything which let you pack and organize the delivery of the goods. Any boxes or bags can be used as a container.

It is important to manage the containers for two reasons. The first is that you might want to manage the stock of containers you have in your company. For instance, if you use boxes to send the goods, you will need to know when you have to buy new boxes.

The other reason why it is important to manage containers, is that you might want to detail which product is placed in which container. The management of containers will be very helpful in case you lose a few containers during the transportation. If you have detailed the Packing List, you will know exactly which goods have been lost.

Packing lists - Customer's point of view

As we just said, we should be as detailed as we can on the Packing List. Depending on who you are working with, they might require general or very specific informations.

For instance, if you are exporting goods, you need to present a very detailed Packing List to the customers. They need to know which specific product is in which specific container. Moreover, they will need even more detailed information such as the weight and the size of every package.

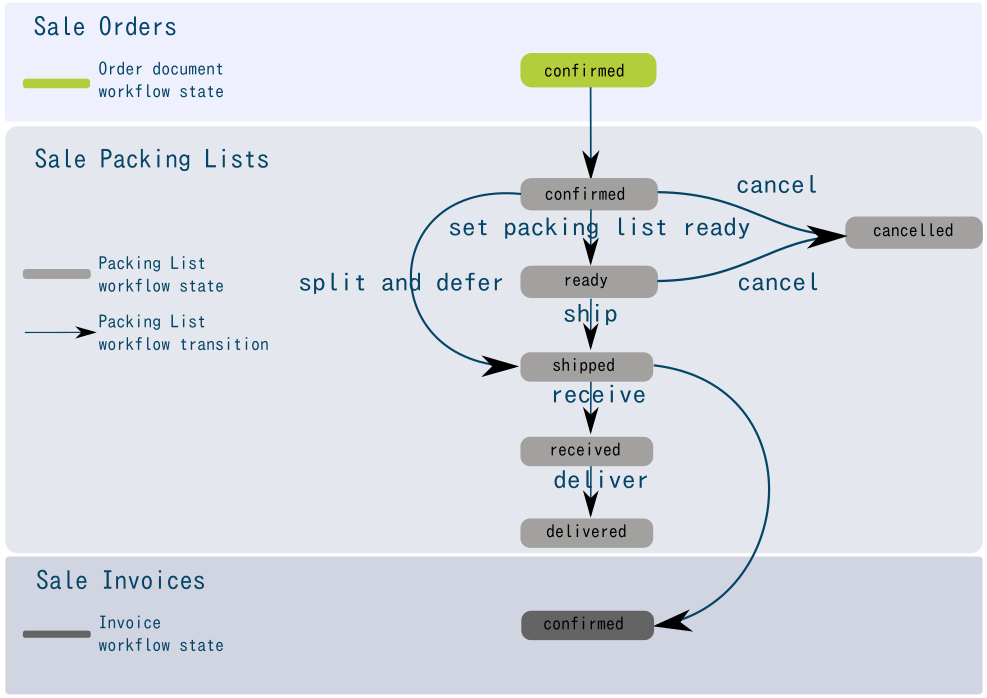

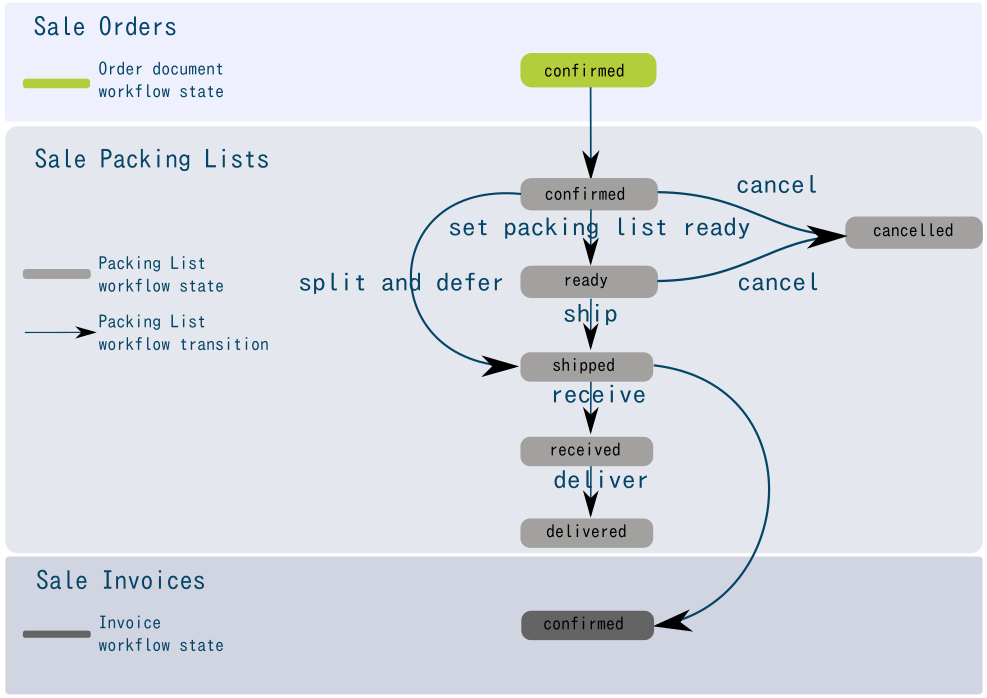

Packing Lists Workflow

In order to manage the Packing List document, we have to firts understand its work-flow.

Once the Order is confirmed, the Packing List is automatically created. This means that the Packing List must be prepared .

Employees in charge of preparing the goods are then able to prepare the goods, and to enter which containers have been used, etc.

They can also decide not to send exactly what has been ordered. For example if they don't have all products which have been ordered.

Once the Packing List has been prepared, they can mark the packing list as "Ready" to be shipped. We will then wait for the carrier to pick up the prepared packing list. Once they pick it up, we will mark the packing list as "Shipped". This will create the related invoice .

When the carrier informs us that the customer has received the goods, we can then mark the packing list as "Received".

When the customer receives the goods, they will check what has been delivered to them. So he or she will compare the packing list we provided to them with what they received. And an error is still possible. Either that we made a mistake while preparing, or maybe that some packages have been damaged etc. So we need to wait until the customer accepts the delivery before marking the packing list as "Delivered".

Note that if the goods ready to be shipped are different from what has been ordered, eg, the quantity is less, you can "Split and Defer" the Packing List before shipping them. In this way, ERP5 will create another Packing List for the remaining goods to be shipped as soon as they are prepared.

Once you ship the Sale Packing List, a related Sale Invoice Transaction will be generated automatically for the next step of the trade process. We will talk about this in the following tutorials.

Packing Lists Worklists

Just like Sale Orders, Packing Lists can be managed through work-lists, which you can access by opening "Worklists" tab on the sidebar. These work-lists are there to summarize the information that you can find also in the Sale Packing Lists module itself.

Thank You

- Rapid.Space

- 147 Rue du Ballon

- 59110 La Madeleine

- France

- +33629024425

- contact (@) rapid.space

For more information, please contact Jean-Paul, CEO of Rapid.Space (+33 629 02 44 25).